Phone : +86 - 18662869458

Phone : +86 - 18662869458

E-mail : linda@no2bearing.com

E-mail : linda@no2bearing.com

What causes the bearing to produce noise?

keywords: bearing noise, bearing

|Causes of bearing noise

1. Excitation caused by the change of the number of loading rollers

When a radial load is loaded on a bearing, the number of rolling bodies carrying the load will change slightly in operation, causing the load direction deviation.

2. Partial damage

Due to operation or installation errors, a small part of the bearing raceway and roller may be damaged. In operation, damaged bearing parts will produce specific vibration frequencies. Vibration frequency analysis can identify damaged bearing components. This principle has been applied in condition monitoring equipment to monitor bearing damage.

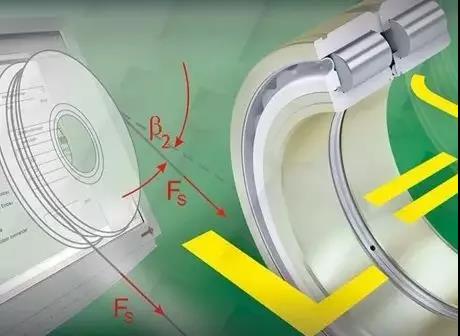

3. Accuracy of relevant components

In the case of close coordination between the inner and outer ring of the bearing and the bearing seat or the drive shaft, the inner and outer ring of the bearing may be deformed due to improper coordination with the shape of adjacent components. If deformation occurs, vibration and noise may be generated during operation.

4. The pollutants

If the equipment runs in a polluted environment, impurities may enter the bearing rolling body and produce vibration sound. In this case, a disturbing noise is usually heard.

5. Other

Rolling bearings produce noise for more complex reasons, one is the bearing inner and outer ring mating surface wear. As a result of this wear, the mating relationship between the bearing and the shell and the bearing and the shaft is destroyed, resulting in the deviation of the axis from the correct position. The shaft produces abnormal sound when moving at high speed.

In addition, insufficient bearing lubrication, the formation of dry friction, and bearing crushing will produce abnormal sound. Bearing wear, cage loose damage, will also produce abnormal sound.

Different bearing noise size is different?

1. The noise of ball bearings is lower than that of roller bearings, and the (friction) noise of bearings with less sliding is lower than that of bearings with more sliding. More balls, thicker outer ring, less noise;

2. The noise of solid cage bearings is relatively lower than that of stamping cage bearings;

3. The noise of plastic cage bearings is lower than that of the above two cages;

4, high precision bearings, especially bearings with higher precision of rolling body, the noise of which is relatively smaller than that of low precision bearings;

5, the noise of small bearings is relatively small than that of large bearings.

Of course, this is the theory, but in practice there are many factors influencing the noise level.

| Experts say - 30 reasons why bearings produce noise

1. Grease has impurities;

2. Retainer fracture;

3. Bearing raceway rusting;

4. Bearing noise (interference from external vibration source);

5. Unqualified ring raceway (manufacturer's problem);

6. The clearance of the bearing is too small or too large (the manufacturer's problem);

7. The diameter of the seat hole is too small (resulting in high bearing temperature);

8. Eccentric sealing ring (encounter adjacent parts and friction);

9. There are sundries in the bearing seat hole (residual chips, dust particles, etc.);

10. Bearing noise (roller end face or steel ball slip);

11. The shaft shoulder is too large (it encounters the seal of the bearing and causes friction);

12 labyrinth seal ring gap is too small (friction with the shaft);

13. The teeth of the lock washer are bent (rubbing against the bearing);

14. The shoulder of the seat hole is too large (the seal on the bearing is distorted);

15. The position of the oil dumping ring is not appropriate (it encounters the flange cover and causes friction);

16. bearing mixed with sand or carbon particles and other impurities, play the role of abrasive;

17. Wear of steel balls and raceway (unqualified grinding or bruised products);

18. The thermal elongation of the shaft is too large (the bearing is subjected to statically indeterminate axial additional load);

19 bearing is flat seat hole clamp (seat hole roundness is not good, or seat hole distortion is not straight);

20. The bearing is mixed with water, acid or paint and other dirt, which plays a corrosive role;

21. The bearing is too loose with the shaft (the diameter of the shaft is too small or the set sleeve is not tightened);

22. The clearance of the bearing is too small and it is too tight during rotation (the tightening sleeve is too tight);

23. There is pressure pit on the steel ball or roller (caused by beating the bearing with a hammer during installation);

24. Bearing discoloration and deformation under heat (caused by heating and disassembly of bearing with spray gun);

25. The shaft is too thick to make the actual fit too tight (resulting in high bearing temperature or noise);

26. Insufficient lubrication (oil level is too low, improper storage leads to oil or grease leakage through the seal);

27. The cushion iron on the bottom of the bearing seat is uneven (resulting in deformation of the seat hole or even cracks in the bearing seat);

28. Bearing seat hole diameter is too large, the actual fit is too loose (bearing temperature is too high, outer ring slip);

29. The bearing seat hole becomes larger (the bearing seat hole of non-ferrous metals is extended, or becomes larger due to thermal expansion);

30. Bearing subjected to additional load (bearing subjected to axial deflection or bearing with two fixed ends on one shaft);