Phone : +86 - 18662869458

Phone : +86 - 18662869458

E-mail : linda@no2bearing.com

E-mail : linda@no2bearing.com

Ball screw - the main force in the transmission field

Keywords: ball screw bearings, ball screw

In the transmission field, ball screw is an indispensable key mechanical component. It is the most commonly used transmission element in tool machinery and precision machinery. Its main function is to convert the rotating motion into linear motion. Because of its very small friction resistance, ball screw is widely used in various industrial equipment and precision instruments. XEZ also make ball screw bearings, except this, our main product is spindle bearings.

01

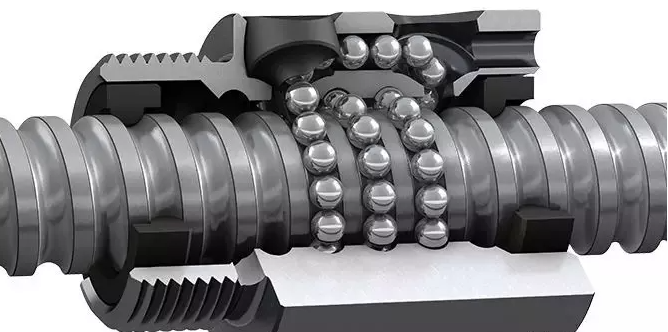

Ball screw is composed of screw, nut, steel ball, prepressing sheet, inverter, dust - proof device. Its function is to transform the rotating motion into linear motion, and to change the bearing from sliding action to rolling action.

In 1898, the first attempt was made to add steel balls between the nut and the screw to convert the sliding contact of the traditional screw into rolling contact. By replacing sliding friction with rolling friction, the rotary motion of the steel ball in the nut is transformed into linear motion, and the torque is converted into axial repeated force, so as to improve the poor positioning and easy damage of the traditional screw.

The ball screw was invented by Rudolph G. Boehm of Texas and was granted a United States patent in 1929.

When the ball screw as the active body, the nut will follow the rotation Angle of the screw in accordance with the corresponding specifications of the lead into linear motion, passive workpiece can be connected through the nut seat and nut, so as to achieve the corresponding linear motion.

The ball screw assembly is metal, usually steel, and consists of a nut with internal threads and a screw, the screw grooves of the nut matching the screw grooves.

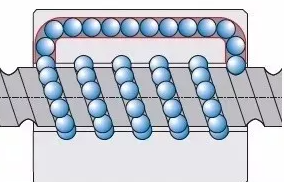

Inside the groove, contained within the nut, are a number of pellets made of chrome steel. When the ball circulates in the nut, the ball provides smooth movement below the screw, and a guide plate or return system holds the ball and circulates them through the nut.

When used with motors, ball screw efficiency is up to 90%. They're pretty accurate, a few thousandths of an inch per foot. Ball screws are used for precise control in many industries, including aerospace, computer, electronics, automotive, and medical.

Ball screws are also frequently used in manufacturing processes and are common in robots, automated assembly lines, material handling equipment, conveyors, machine tools, wire controls, and precision assembly equipment.

02

The ball screw assembly consists of a screw and a nut, each with a matching spiral groove through which the ball rolls, providing sole contact between the nut and the screw.

When the screw or nut is rotated, the balls are deflected by a deflector into the ball return system of the nut, and they travel in a continuous path through the return system to the opposite ends of the ball nut. The ball is then withdrawn from the return system into the ball screw and nut thread raceways for recirculation in the closed loop.

The ball nut determines the load and life of the ball screw assembly. The ratio of the number of threads in the ball nut loop to the number of threads on the ball screw.

Ball nuts will reach the point of fatigue failure (wear) more quickly than ball screws.

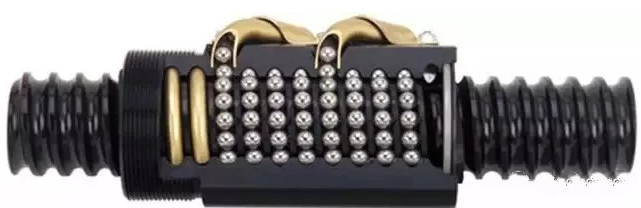

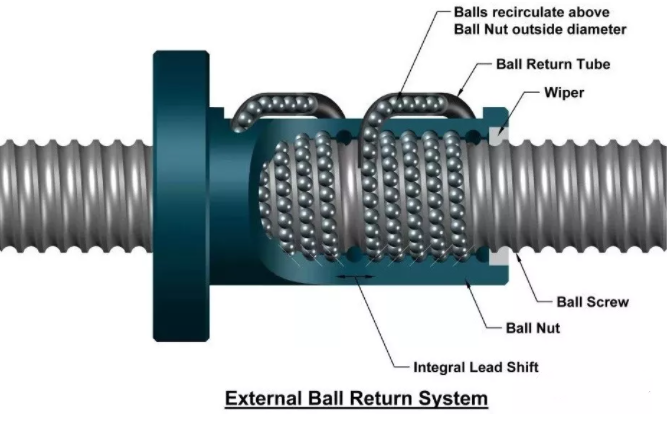

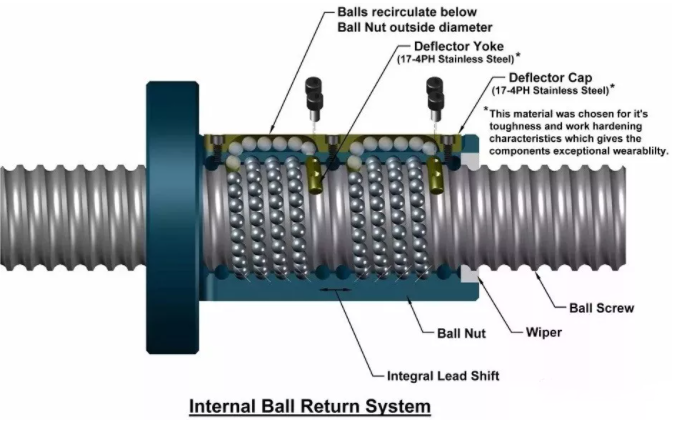

Ball nuts contain two types of ball return modes, external and internal circulation.

External circulation: the ball returns to the opposite end of the loop through a return tube that protrudes above the outer diameter of the ball nut.

Internal circulation: ball returns through or along the wall of the nut, below the outer diameter of the ball nut.

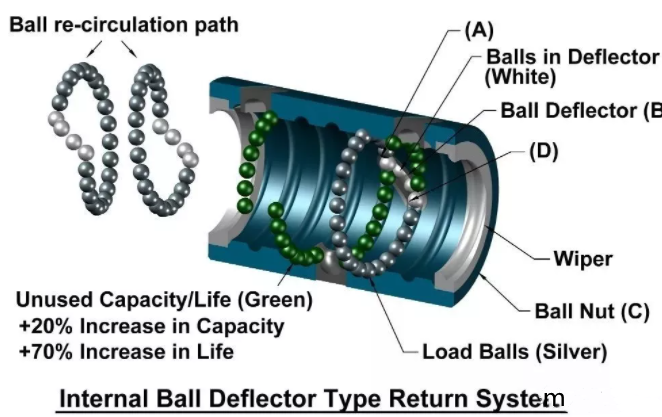

The internal loop has a rotating loop (shown above), and the ball is forced to climb over the top of the thread on the screw through the return system. This is called the cross deflector type internal return system. In A cross deflector type ball nut, the ball rotates the shaft only once and the loop is closed by A ball deflector (B) in the nut (C), allowing the ball to cross (A) and (D) between adjacent grooves at the point.

When the long ball screw is rotated at high speed, it will start to vibrate as soon as the slender-to-slenderratio reaches the natural harmonics of the shaft size. This is called the critical speed and can be very detrimental to the life of the ball screw. (Safe operating speed should not exceed 80% of the critical speed of the screw)

Some applications require longer shaft lengths and higher speeds, which are where rotation of the ball nut assembly is required.