Phone : +86 - 18662869458

Phone : +86 - 18662869458

E-mail : linda@no2bearing.com

E-mail : linda@no2bearing.com

Those who know bearings know that the installation process of angular contact ball bearings is more complex than that of deep groove ball bearings, and most of them are installed in pairs, and preloading is required. Whether the installation of angular contact ball bearings is correct or not will affect the accuracy, life and performance of bearings. If the installation is well, the working precision and bearing life of the main engine can be greatly improved. Otherwise, not only the accuracy is not up to the requirements, but also the life will be affected. Because the single row of centripetal angular contact ball bearings can only withstand the axial force in a single direction. Some occasions in order to be able to withstand bidirectional axial force, at least two rows of bearings need to be combined to achieve this purpose, or to improve the axial single direction of the load, need to use at least two rows of bearings in series combination, so, it is because of this, angular contact ball bearings should be installed in pairs.

When installing angular contact ball bearings, notice that the bearing ring can adapt to the rolling of the rolling body, and ensure that the rolling body is on the upper and lower ring raceway. The installation method of diagonal contact ball bearings is as follows:

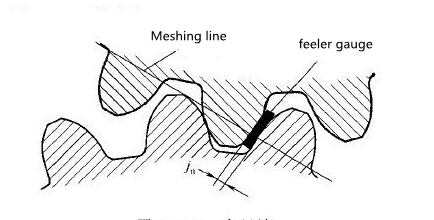

1.Usually the feeler detection method is used to detect, for the larger diameter angular contact ball bearings, the clearance is very large, and the narrower feeler should be used for direct measurement. For small diameter angular contact ball bearings, the clearance will be very small, and there is no need to use a feeler gauge to measure, then the clearance of diagonal contact ball bearings will be measured, and the thickness of the feeler will be used to measure.

2. Another way is to pressure lead to measure, measure diagonal contact ball bearing clearance, if you use a feeler will be very trouble, so, we usually adopt soft lead wire in the actual work measured, using the soft lead wire is measured, using soft lead wire should be very soft, not the etheric long or too small in diameter. The ideal direct clearance is 1.5-2 times.

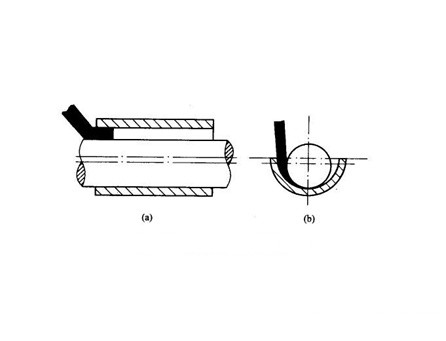

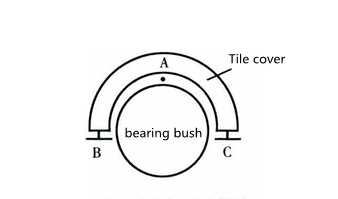

During the inspection, open the lid of the cover contact ball bearing first, choose the appropriate soft lead wire, cut into small pieces placed on bearing neck and bearing interface up and down, cover in the bearing cover, tighten the screw bolt, unscrew the bolt, then remove the bearing cover, flattening of lead wire is measured with a micrometer thickness, average angular contact ball bearing of the tip clearance are obtained. If the gap is too small, can be in the upper and lower tile combined with the surface of the mat, if too large, then reduce the pad or re pouring tile. After the end of installation and detection, ball bearings can operate normally if there is no abnormal angular contact.