Phone : +86 - 18662869458

Phone : +86 - 18662869458

E-mail : linda@no2bearing.com

E-mail : linda@no2bearing.com

Speaking of bearings, they almost exist in every corner of our lives. Most mechanical equipment we can think of has its existence, such as vibration motors in mobile phones, computer cooling fans, and even shared bikes, washing machines, planes in the sky, ships in the sea... All rotating parts need bearings.

This little bearing seems insignificant, but it is also an important standard to measure a country's scientific and technological and industrial strength, and is regarded as "the joint of high-end equipment". Like many fields, China has long been the world's largest production and sales base in the field of low-end bearings, but high-end bearings did not finally make a breakthrough until recently.

1. how harsh the working environment of bearings is, you may not imagine

Bearings, as the name suggests, is to support the rotating shaft, or linear axis of motion parts, its role is to provide support for the rotating body or linear back and forth movement body in machinery, when other parts on the shaft relative movement, the bearing can maintain the central position of the shaft and control the movement.

Its type is extremely complex, simple to divide, can be divided into two kinds, rolling bearings and sliding bearings. No matter what kind of bearing, its main function is to support the rotating body in motion. In order to ensure mechanical efficiency and rotary accuracy, it requires that the rotating body has a low friction coefficient in the process of movement. Therefore, the smaller the vibration between the shaft and the bearing, the less wear and tear, the lower the heat, the better.

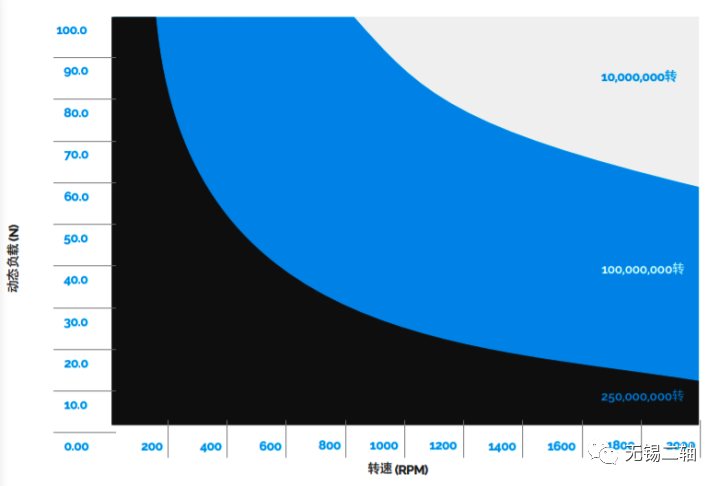

Taking rolling bearings as an example, when it starts to work, the inner and outer ring of the bearing and the rolling body of the bearing will bear the role of high frequency and variable stress. The contact area between the rolling body and the ring is very small, and the unit area will bear a lot of pressure, generally up to 1500-5000N/mm^2. At the same time, the rolling bearing also bears the action of centrifugal force, and the centrifugal force will increase with the increase of the speed.

Under the action of such high frequency and variable stress, the surface of the ring or rolling body is easy to produce stress fatigue, and finally, fatigue cracks are generated in the parts with low fatigue strength, forming fatigue spalling, and making the bearing damaged and ineffective.

(The load and speed of the bearing at work are important factors to determine the life of the bearing)

In addition to the stress extrusion and friction brought by the high-speed rotation process, bearings working under special conditions have special requirements, such as high temperature resistance, low temperature resistance, corrosion resistance and diamagnetism, etc., and the working conditions of bearings are very complex.

(TBM and its main bearing)

2. to make high-end bearings working under harsh conditions, there must be good steel

High-end bearings are needed on high-end equipment such as high-speed railway, large aircraft and heavy-duty weapons. In order to meet the requirements of high-end bearings in precision, performance, life and reliability, the high quality and reliability of bearing materials are the decisive factors.

(Air Force ground crew is maintaining F110 engine fan bearings of F15 fighter jets.)

In the four components of rolling bearings, in addition to the retainer, the inner and outer rings and the rolling body (ball, roller or needle) are composed of bearing steel, and bearing steel has the title of "the king of steel", which is the most stringent steel in steel production.

Bearing steel also has many kinds, according to the use of different requirements, chemical composition is not the same, among which high carbon chromium bearing steel accounts for a large proportion, is the most commonly used steel manufacturing bearings and bearing parts.

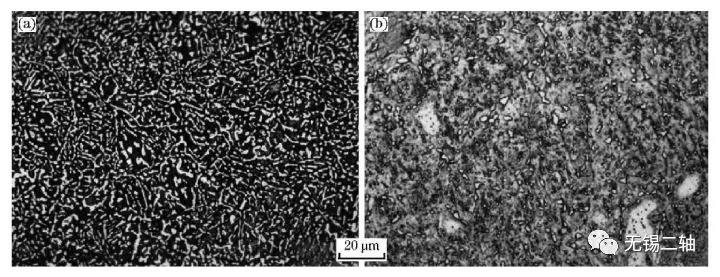

The quality of bearing steel mainly depends on the following four factors: first, the content, shape, distribution and size of inclusions in the steel; Second, the content, shape, distribution and size of carbides in steel; Third, the central porous shrinkage cavity and central segregation in steel; Fourth, the consistency of bearing steel product performance. These four factors can be summarized as purity and uniformity indexes.

Among them, the purity requires the inclusion in the material as little as possible, the purity has a direct impact on the fatigue life of the bearing; The uniformity requires the inclusion and carbide particles in the material to be fine and diffuse, which will affect the deformation and microstructure uniformity after heat treatment in bearing manufacturing.

(uniform fine carbide structure in high-end bearing steel and uniform fine carbide distribution after heat treatment)

To improve the purity of bearing steel, the first thing to do is to control the oxygen content in steel. Steelmaking uses PPM (one part per million) as the unit of oxygen content. Generally speaking, 8 PPM of steel belongs to good steel, while high-end bearings need 5 PPM of top steel. In addition, titanium and other harmful elements in the steel is easy to form multiple edges and corners of inclusion, will cause local stress concentration, fatigue crack, which should be avoided as much as possible.

At present, with the improvement of the steel platform for the high purity of smelting system, bearing steel purity had the very big enhancement, to effectively control inclusions level, in the developed countries of oxygen content in steel has been controlled in 5 parts per million, so the content of carbide in steel, distribution, size, and so on gradually became the main factors restricting the quality of bearing steel.

3. With bearing steel, China's bearing technology is one step closer to the world's top level

The demand for bearings of a country always maintains a certain relationship with the GNP, and the production capacity and level of bearing steel is the key restricting factor for the development of bearing industry. Therefore, the industrial developed countries have always attached great importance to the production, quality and research and development of bearing steel.

Ago, high-end research and development, manufacture and sales of the bearing steel has been the United States, Sweden and other countries of bearing giant monopoly, how to obtain high purity and uniformity good top steel, has always been the core technology giant shrouded in secrecy, they even purchase low-end material from China, finally processed into high-end bearing, again with dozens of times of the price to sell into the Chinese market.

(a continuous caster producing continuous cast bearing steel)

For a long time, China's bearing steel production is high, but the quality level is low, especially in the aspect of high-end bearing steel, there is a big gap with the advanced level of foreign countries, there are some problems, such as the content of trace impurity elements in steel is high, the oxygen content level is two or three times higher than the international advanced level, and the morphology uniformity of carbides in steel is poor.

After more than ten years of efforts, China has become a big bearing steel production, overcome many difficult problems in the production process of bearing steel, such as oxygen content control in the world's advanced level of less than 5ppm, master the core technology of its internal quality control.

Adding rare earth in addition, the steelmaking process, make originally the high quality steel become more "strong", is to solve the technical direction of high-end bearing steel, this kind of technology that is at the heart of the world bearing giants secret, now is also China's scientific research personnel, Chinese scientists will influence the fatigue life of large size in rare earth bearing steel inclusion amount decreased by 50%.

Nowadays, China can not only make high-end bearing steel, but also break out a reputation in the international market. China's bearing steel has been supplied to Sweden, Germany, Japan and other countries. At the same time, the fatigue life of high-end bearing steel has reached or even exceeded that of Japan and Europe in the same period.

With good steel, the next step is to solve the bearing problem, research and development of high-end bearing involving materials, design, bearing manufacturing equipment, high precision machining, inspection and test and a series of technical problems, also need to contact mechanics, lubrication theory, tribology, fatigue and damage, heat treatment and material organization support for basic research and interdisciplinary, High-end bearing technology is extremely complex and difficult to master.

At present, domestic bearings, compared with imported high-end bearings, the gap in accuracy, bearing vibration, noise and abnormal sound, reliability and high-speed performance is narrowing step by step.

conclusion

High-end bearings, like chips, are the core technologies that China must master. Although there is still a long way to go to catch up, China has built a good industrial base in the field of bearings, and is fully capable of catching up with the world's advanced level in the foreseeable future.